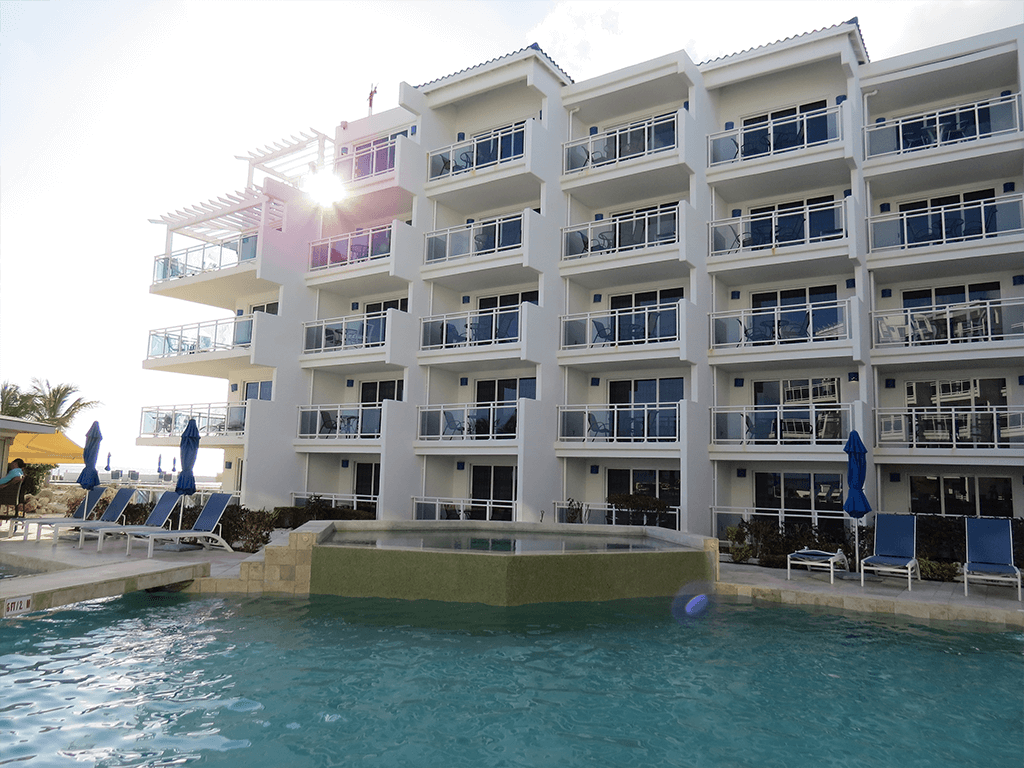

Domestic wastewater treatment plants of 75 m³ per day and above are typically located in holiday home communities, residential areas, hotels, restaurants, villages and cities.

AAA wastewater treatment plants, specially designed for your needs, are a reliable choice worldwide. Our systems stand out with their impressive performance and versatility. AAA technology is designed to be extremely safe and durable, offering a high degree of flexibility to adapt to the specific requirements of a wide range of applications. It produces optimized solutions for a wide range of usage areas, from commercial facilities to municipal facilities.

More than 30 years of experience

in more than 70 countries around the world

Technology

Effective treatment of various wastewaters requires competence in a variety of techniques.

MBR

Membrane Bioreactor

MBBR

Moving Bed Biofilm Reactor

SBR

Sequencing Batch Reactors

Your project is

in the best hands with us

We offer sewage treatment plants specifically designed for domestic wastewater with volumes of more than 75 m³ per day for both commercial and private purposes. These projects require absolute customer proximity, a high level of expertise and many years of experience. That’s why we accompany you in every phase, from the first contact to the successful completion of your project.

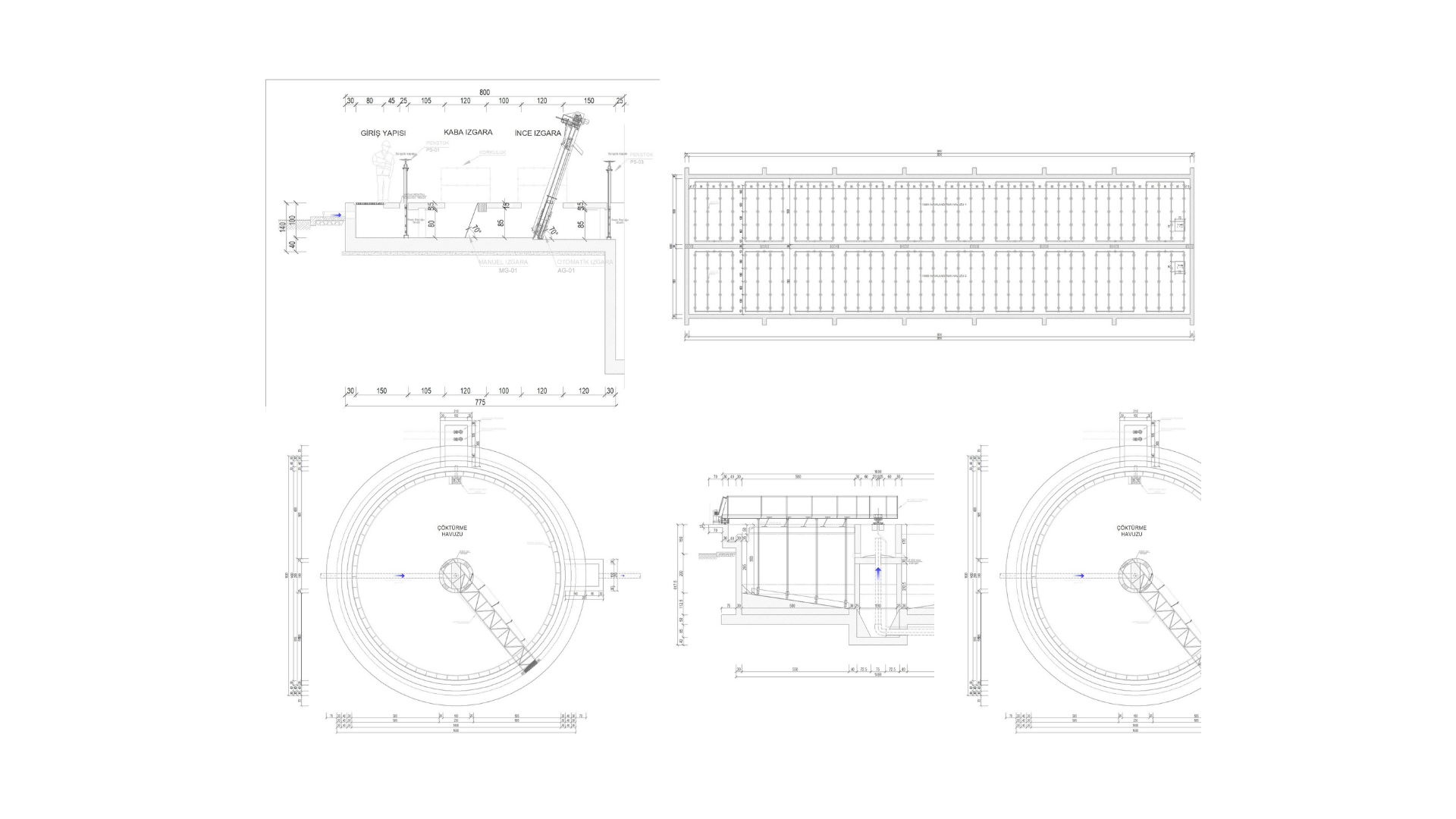

Fully aerobic wastewater treatment with SBR technology

– in the segment up to 1,500 m³/day

As the authorized distributor of the German market leader KLARO in Turkey, we can offer you the unique advantages of Klaro MAX technology with complete ventilation of clarification rooms in the segment of up to 10,000 users. Considered down to the smallest detail, reduced to the easiest and most robust parts possible, this technology not only completely rids you of odor, but also guarantees minimum operating and maintenance costs.

AAA gives you maximum flexibility

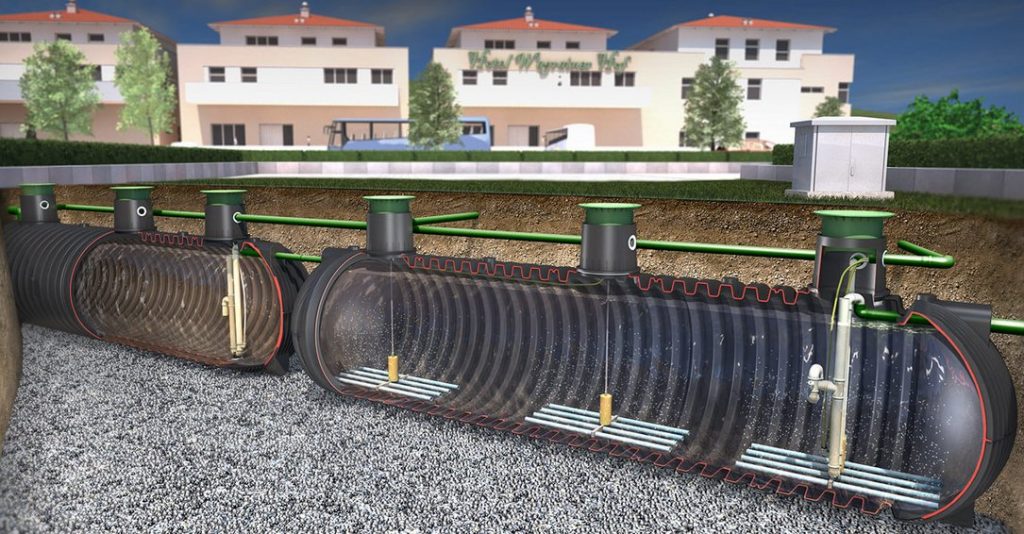

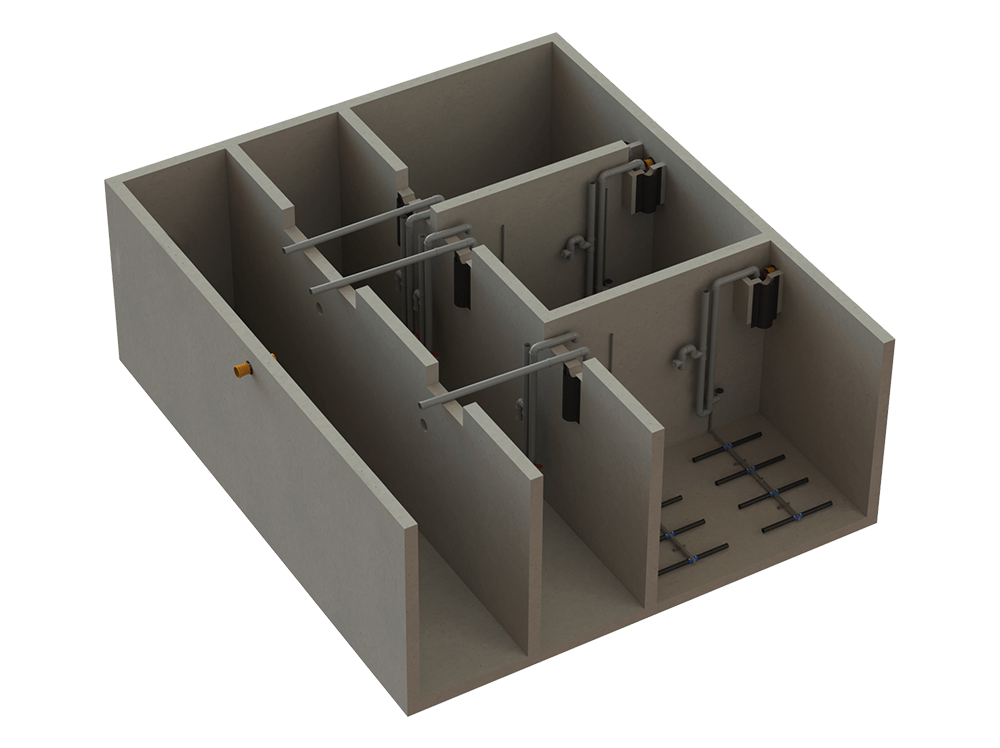

Thanks to our flexibility, there are no limits when designing the infrastructure for your AAA wastewater treatment plant.

By installing your wastewater treatment plant in plastic tanks, you save yourself the hassle of concrete construction work.

If underground installation is not possible or your wastewater treatment plant will only be used in one location for a limited time, our container solutions may be suitable for you.

AAA is an Authorized Distributor of KLARO

A title

Image Box text

STRONG

Proven KLARO SBR concept

SIMPLE OPERATION

LOW MAINTENANCE INTENSITY

FULLY AUTOMATIC BACKWASH FUNCTION OF THE DECANTER TO PREVENT SUSPENDED SOLIDS DISCHARGE

NO DISTURBING FLOW DURING SEDIMENTATION

SAFE

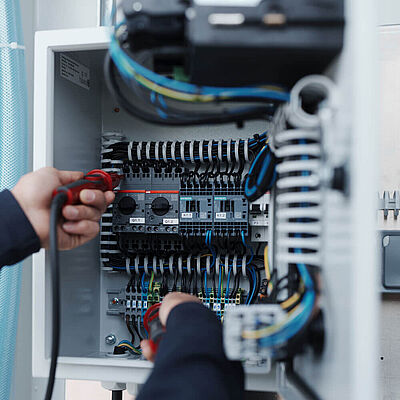

ELECTRICAL AND MECHANICAL COMPONENTS PROTECTED IN A SEPARATE MACHINE ROOM

ONLY WASTEWATER-RESISTANT COMPONENTS IN THE WASTEWATER TREATMENT PLANT

ONLY SELECTED, HIGH-QUALITY COMPONENTS

INDIVIDUAL

MODULARLY EXPANDABLE

CONSIDERATION OF LOCAL CONDITIONS, CLIMATE AND SPECIAL REQUIREMENTS IN DESIGN

DOMESTIC AND COMMERCIAL WASTEWATER

TECHNICAL SERVICE ON REQUEST

EFFICIENT

LOW ENERGY CONSUMPTION

FULLY AUTOMATED AND USER-FRIENDLY

LOW-MAINTENANCE, LOW-WEAR COMPONENTS

SBR TREATMENT PROCESS

ACHIEVABLE DISCHARGE VALUES: BOD5 <10 mg/l TN <10 mg/l COD <50 mg/l NH4N <5 mg/l SS <15 mg/l TP <1 mg/l

WATER IS VALUABLE

Reduce your costs and help the environment…

Learn more about water reuse with KLARO BLUE.CYCLE. Our aim is to ensure that the water used in the treatment system can be used directly, i.e. for garden irrigation. The KLARO blue.cycle® is the result of long and intensive research and development by KLARO and is made for the disinfection and reuse of water and is designed to be installed as an addition to wastewater treatment systems.

EXTENSION

KLARO WEB MONITOR – INTELLIGENT REMOTE MONITORING

Smart home

KLARO WebMonitor® is an internet portal that allows maintenance companies and operators to monitor small wastewater treatment plants online wherever they are located.

Biological SBR-treatment process

ClarIfIcatIon through bIologIcal purIfIcatIon

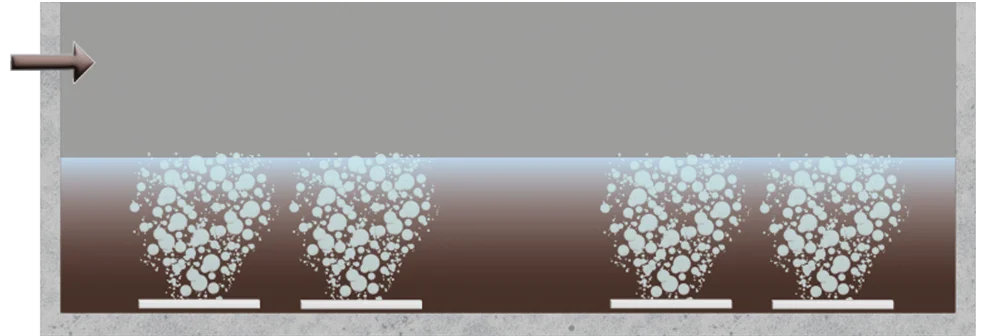

1. AERATION

The raw wastewater is fed into the bioreactor of the plant and is treated biologically. Strip diffusors on the bioreactor floor ensure sufficient aeration and mixing of the entire bioreactor. The air required for this is generated by a rotary piston compressor in the machine house.

Aeration usually takes place intermittently. The microorganisms are thus optimally supplied with oxygen to efficiently treat the wastewater. Mixing for denitrification is ensured by short aeration sequences.

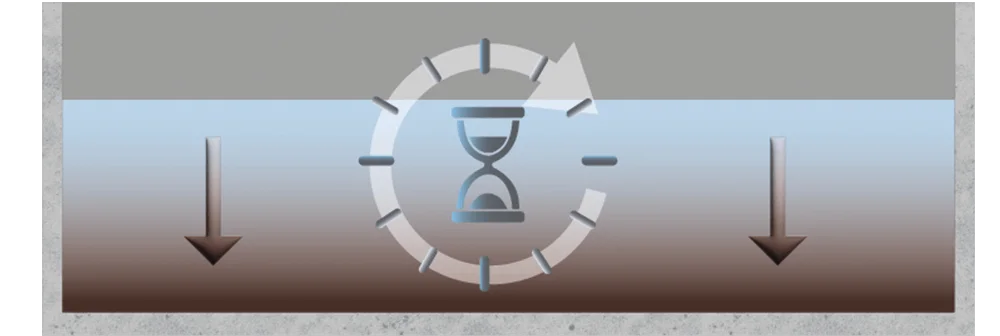

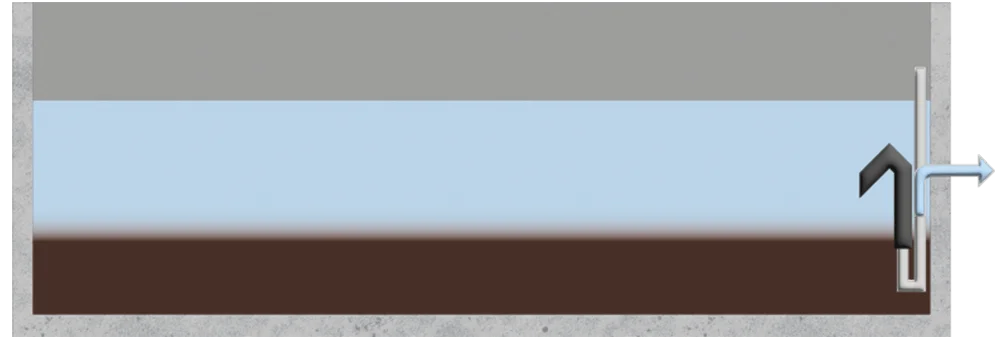

2. SEDIMENTATION

Aeration is followed by sedimentation, also known as the settling phase. During this phase, the reactor contents calm down and the activated sludge settles. In order not to disturb the sedimentation, inflowing raw sewage is channelled into the pre-storage tank (one-line systems) or into the second bioreactor (two-line systems).

3. BACKWASH & DISCHARGE

After a certain time, the separation of clear water and sludge is so clear that the discharge can start. To ensure that suspended solids in the decanter do not reach the effluent, it is backwashed with the aid of a compressed air lift before each discharge. The contents are pumped back into the bioreactor. Afterwards the butterfly valve opens and the clear water is discharged from the bioreactor by gravity.

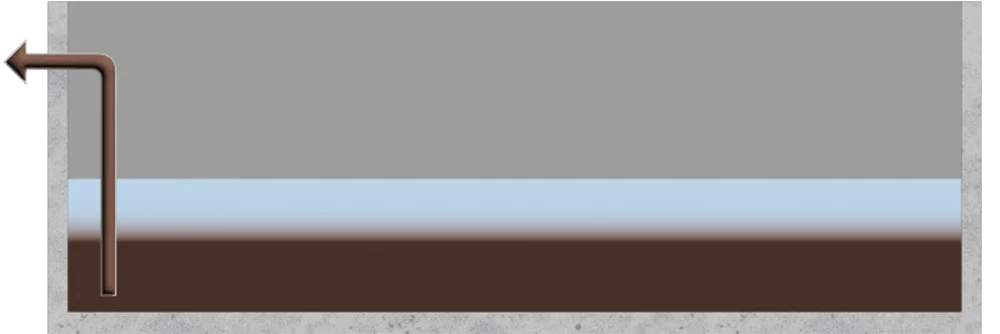

4. SLUDGE RETURN

In the final step of the cleaning process the excess sludge is removed. The excess activated sludge formed is channelled from the bioreactor into the sludge storage tank via a sludge pump. As soon as this process is complete the continuously flowing raw wastewater runs back into the bioreactor. In one-line systems, the pre-storage tank is also emptied and the treatment process starts again from the beginning with aeration.

Get in touch

Give us initial information about your wastewater project and our experts will be happy to get in touch with you immediately.